Tray Forming Machines Used in the Food Industry Generally Have 9 Characteristics

What Is a Tray Former?

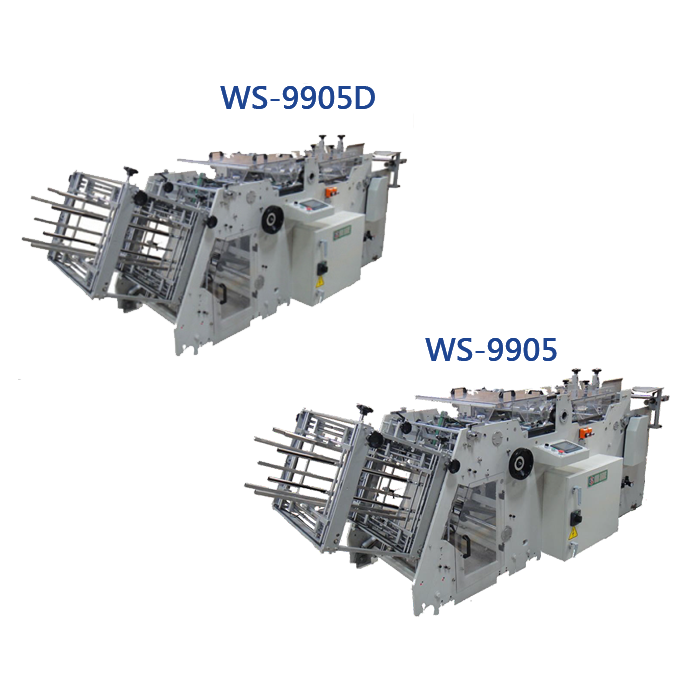

The tray former is also called tray forming machines, which can produce paper trays in efficient rapid for food industry to apply on. Tray formers from WinShine have the following characteristics.

1. Automated Operation: Tray formers are typically fully automated, designed to streamline the tray forming process. They can perform various tasks automatically, such as feeding the tray blanks, forming and folding the trays, and ejecting the finished trays.

2. Versatility: These machines are designed to accommodate different tray sizes, shapes, and materials. They can be adjusted or reconfigured to handle various packaging requirements and adapt to different food products.

3. Speed and Efficiency: Tray formers are built for high-speed production, capable of forming trays at a rapid rate. They are engineered to optimize efficiency and maximize productivity in food packaging operations.

4. Custom Options: Tray former machines often offer customization options to cater to specific packaging needs. This includes the ability to create trays with different compartments, inserts, or special features to accommodate specific food products or packaging requirements.

5. Material Handling: Tray formers are equipped with systems to handle tray blanks and materials efficiently. They can handle different types of tray materials, such as paperboard, corrugated cardboard, or plastic, depending on the specific machine design.

6. Control Systems: Tray formers feature control systems that allow operators to set parameters, adjust settings, and monitor the production process. These control systems may include touchscreen interfaces or digital controls for easy operation.

7. Quality and Reliability: Tray formers are designed to ensure the consistent production of high-quality trays. They incorporate mechanisms for precise folding, sealing, and stacking of trays to maintain their integrity and durability during transportation and storage.

8. Safety Features: These machines are equipped with safety features to protect operators and prevent accidents. This can include emergency stop buttons, safety guarding, and sensors to detect and mitigate potential hazards.

9. Easy Maintenance: Tray formers are designed for easy maintenance and cleaning. They often have accessible components and modular designs that allow for quick repairs, part replacements, or cleaning procedures.

10. Integration Capabilities: Tray formers can be integrated into larger packaging systems or production lines, allowing for seamless automation and coordination with other machines, such as filling machines, labeling machines, or conveyor systems.

Why Use Tray Former Machines?

Food paper tray boxes are a convenient and eco-friendly option for packing and carrying food in Latin America. They are made of biodegradable materials that can be recycled or composted after use, reducing the environmental impact of disposable packaging. Food paper lunch boxes can be used for various purposes, such as:

- Catering for events, parties, or meetings

- Delivering food to customers or employees

- Storing leftovers or prepared meals in the fridge or freezer

- Promoting a brand or a cause with customized designs and logos

Food trays and boxes are also hygienic and safe, as they prevent contamination and preserve the freshness and quality of the food. They are easy to handle and transport, as they are lightweight and stackable. They can also be customized to fit different sizes, shapes, and types of food, such as sandwiches, salads, soups, or desserts. Food paper lunch boxes are a practical and sustainable solution for food packaging in Latin America.

Tray formers used in the food industry generally possess certain characteristics and features to efficiently form trays or containers for packaging food products. It is a trend in recent years. If you need more tray former or other machines like paper plate machines or paper bowl machines, welcome to contact WinShine!