How to Make Plastic-free Paper Cups by Win Shine Paper Cup Machines

Why Food Paper Containers Become a Trend?

According to statistics, Taiwan will produce about 8 billion paper lunch boxes every year. In the past two years, due to the epidemic situation, the number of paper lunch boxes has been hitting a new high. From only 80,000 metric tons in 2019, by 2020 and 2021, it will be just 160,000 metric tons of paper lunch boxes are produced. The number of paper lunch boxes alone is astonishing every year. However, there are currently only three processing plants in Taiwan that can process this kind of paper container with coatings. So have you ever thought about what if paper lunch boxes and tea cups are all made of paper?

How to Make Plastic-free Paper Cups by Win Shine Paper Tea Cup Machines?

Huazhi has an all-paper material base in the Guanyin Factory in Taoyuan. They use WinShine paper cup machine, a paper cup testing machine The main purpose is to confirm that the relevant quality can achieve waterproof, oil-proof and heat-sealable characteristics during the research and development process.

How to Use Paper Tea Cup Machines?

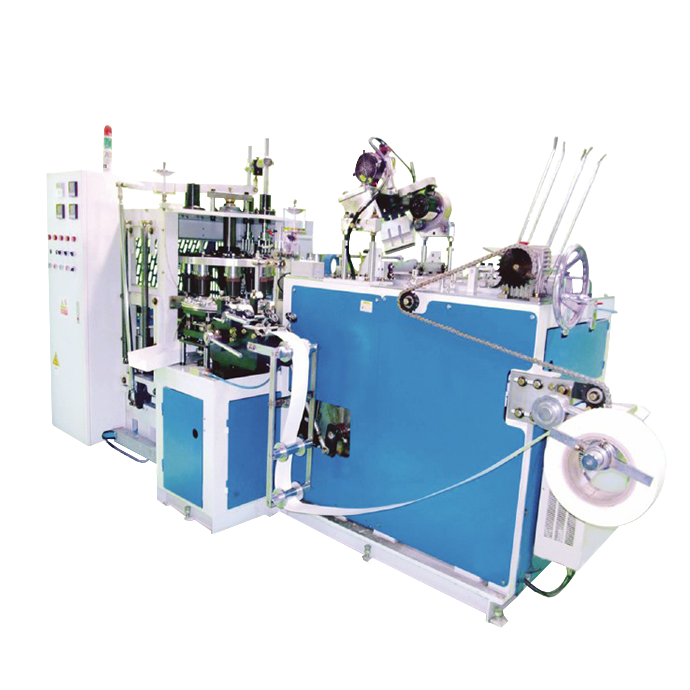

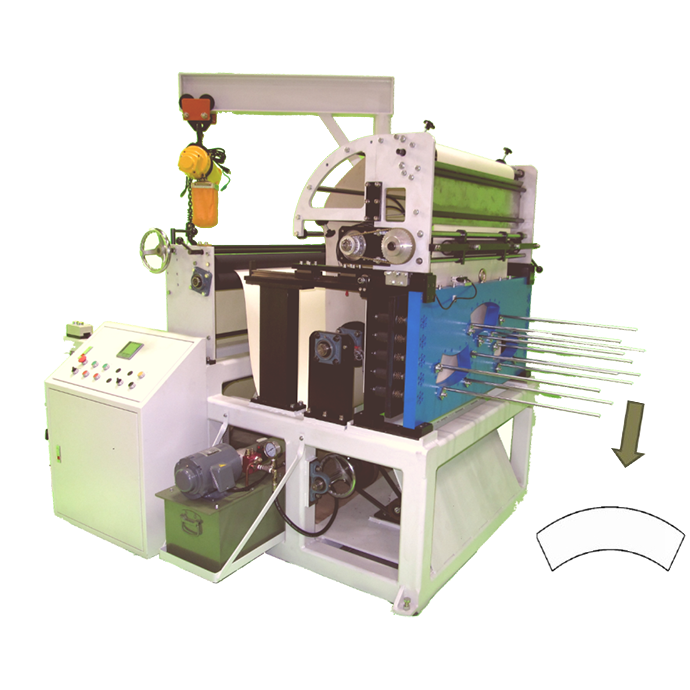

The structure of the whole paper cup can be roughly divided into two parts, one is the cup body, which is the bottom of the cup, and the production paper roll at the bottom of the cup, there will be a die-cutting mold under the machine, its function is to punch our entire cup piece into the shape of the bottom of the cup, similar to the feeling of cutting, cutting After cutting and shaping it into a shape, it will be combined with the cup body later. The cup body is also made of all-paper material, and then processed and cut on the outside to become a fan. There is no plastic coating on the top. In fact, it is also smooth, and it will be placed in the paper feeding area.

After putting it in, the whole stack becomes paper, and the paper cup machine will absorb one by one and send it forward to the forming block of the cup body. There will be a tool to clamp it up. This equipment uses an ultrasonic heating probe. , it can be heated and clipped and then glued to the state of the cup body, and then sent later. We will put the newly made cup bottom and cup body together. Of course, the process includes heating under the cup, and then folding, Embossed and fixed, the part of the lip of the cup will help it fold back into the way we usually drink, What is the most critical technology is heat forming, because we do not use any glue in all the processes, all through the front ultrasonic wave (heating) and the back part is heat-sealed, after heating, press and then carry out Glue and the mug is complete.

The quality inspection related to the paper cup will be carried out next, so the quality control personnel will tear the whole paper cup to make sure, that is, the paper is broken, which means that the adhesive surface of the entire cup body and the bottom of the cup is very complete, and the inspection stage is completed. If you are interested in our paper tea cup machines and other paper container making machines, welcome to click the following related machines.