Products

Win Shine Machinery has dedicated ourselves to developing high-quality paper food packaging box making machine to meet the needs of our customers.

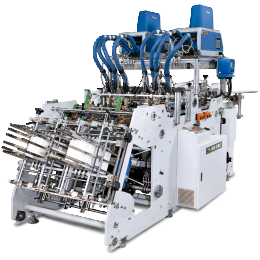

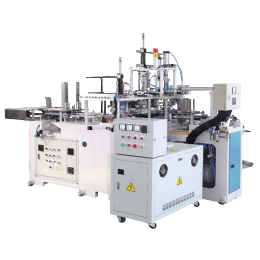

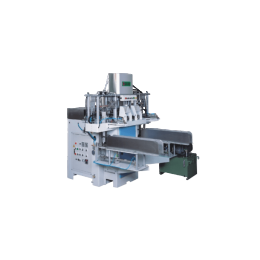

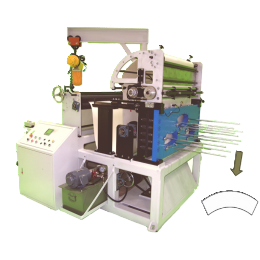

Main Products:Variety of 1~5 Compartment paper lunch box forming machine,Carton Erecting Machine for Hamburger Box, Paper box for French Fries or cakes, Paper tray and Food pail Box,Food Pail Forming Machine, Paper Pail Forming Machine, Food Container Forming Machine, Paper Pail, Fold-Pak, Takeout Box, Takeout Containers,Disposable Paper Take Out Food Containers,Automatic Paper Cup Machine / Paper Plate and Bowl Making Machine.

For the production of paper cups, paper trays, and paper lunch boxes, we provide the purchase guide of environmentally friendly professional paper food packaging box making machines.

The rise of automation and integration in the paper lunch box machine market is transforming the industry, driven by technological advancements and increasing demand for efficient production processes. Here are the key factors contributing to this trend:

-

Advanced Automation

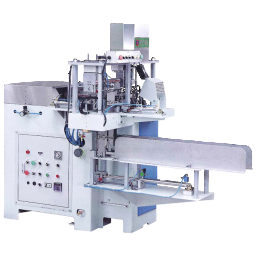

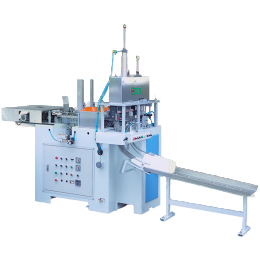

Fully Automatic Machines: These machines are becoming the industry standard due to their high efficiency and ability to produce large quantities with minimal human intervention. They are equipped with features like auto paper feeding, forming, and ejection, significantly reducing labor costs and increasing productivity.

Integration of IoT and RFID: Modern paper lunch box machines are integrating Internet of Things (IoT) technology and Radio-Frequency Identification (RFID). This integration allows for real-time monitoring, predictive maintenance, and improved inventory management, enhancing the overall operational efficiency.

-

Smart Manufacturing:

Data Analytics and AI: The use of data analytics and artificial intelligence in paper lunch box manufacturing is enabling more precise control over the production process. These technologies help in optimizing machine performance, reducing waste, and improving the quality of the final product.

Automated Quality Control: Advanced sensors and imaging technologies are being integrated into machines to automatically detect defects and ensure consistent quality. This reduces the need for manual inspections and minimizes errors.

-

Customization and Flexibility:

Multi-Function Machines: There is a growing demand for machines that can handle multiple functions, such as producing different shapes and sizes of lunch boxes. These versatile machines cater to diverse customer needs and can be easily adjusted for various production requirements.

Software Integration: Modern machines come with sophisticated software that allows for easy customization and programming. Manufacturers can quickly switch between different product specifications, enhancing their ability to meet changing market demands.

-

Sustainability and Efficiency:

Energy-Efficient Designs: Newer models of paper lunch box machines are designed to be more energy-efficient, reducing operational costs and environmental impact. This aligns with the increasing consumer preference for sustainable packaging solutions.

Waste Reduction: Automation helps in minimizing material wastage during production. Precise control over cutting and forming processes ensures that paper resources are utilized efficiently, contributing to cost savings and environmental sustainability.

-

Global Expansion and Market Growth:

Emerging Markets: The adoption of automated paper lunch box machines is rapidly increasing in emerging markets such as Asia-Pacific and South America. These regions are experiencing significant growth due to urbanization, rising disposable incomes, and the shift towards sustainable packaging.

Strategic Collaborations: Companies are forming partnerships and collaborations to leverage advanced technologies and expand their market presence. These strategic initiatives are driving innovation and enabling companies to offer more integrated and comprehensive solutions.

In conclusion, the rise of automation and integration in the paper lunch box machine market is revolutionizing the industry. With the implementation of advanced technologies, manufacturers are achieving higher efficiency, better quality control, and greater flexibility in their production processes. These developments are crucial for meeting the increasing global demand for sustainable and cost-effective packaging solutions.